Important Announcement

In an effort to better serve you, we have consolidated our APTS Testing and Processing services with the National Polymer Innovation Center (NPIC). All our same capabilities are here, just under a different name. Contact Dr. Todd Lewis at 330-972-7349 or tml4@uakron.edu to get started with a project today.

Welcome to the National Polymer Innovation Center (NPIC)

The National Polymer Innovation Center (NPIC) is a contract services facility at the leading edge of advanced manufacturing and materials characterization. Supporting industry, national laboratories and the School of Polymer Science and Polymer Engineering at The University of Akron, NPIC offers solutions in pilot-scale processing, surface and structural analysis, physical and chemical characterization, and more.

In addition to our own capabilities, our affiliation with the School of Polymer Science and Polymer Engineering gives us access to experts in coatings, electronics, functional materials, films, nanocomposites, adhesion, membranes, sustainability, and biomaterials. Let us be your partner in solving your business-critical materials challenges!

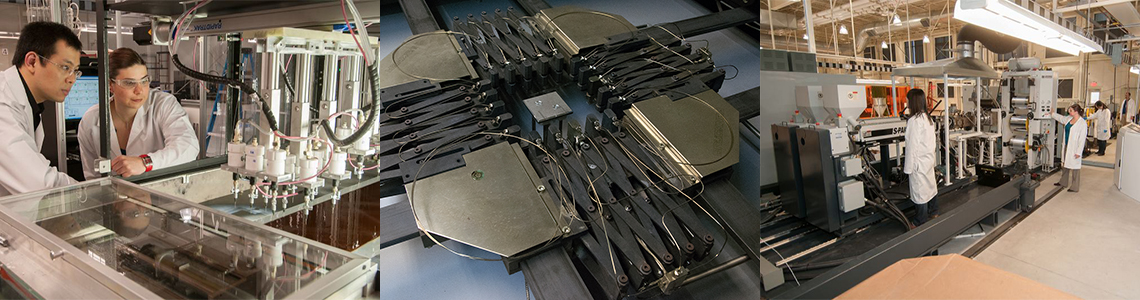

Pilot Processing and Advanced Manufacturing

We offer pilot scale Multi-layer Cast Film Coextrusion, Electromagnetic Alignment Solution Casting, Hybrid Solution Casting with Electrospun Nanofibers, UV/IR Co-Curing, and more!

NPIC is also capable of small batch traditional plastics and rubber processing.

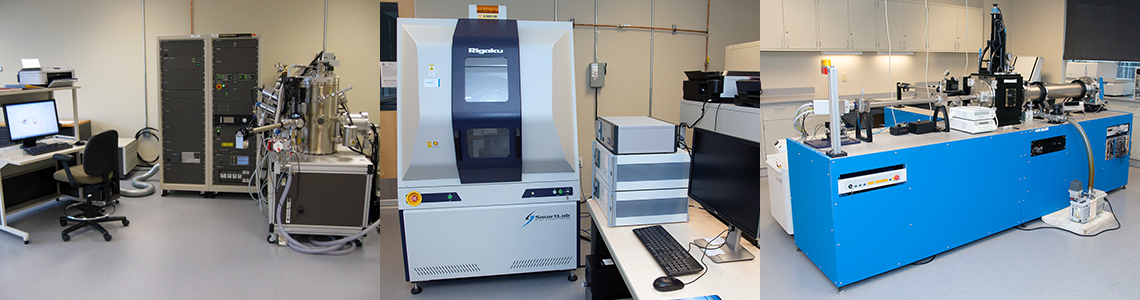

Materials Characterization

Our state-of-the-art facilities include X-Ray Photoelectron Spectroscopy (XPS), Auger Electron Spectroscopy, X-Ray Micro Computed Tomography (micro CT), X-Ray Diffraction (XRD), Small Angle X-ray Scattering (SAXS), Raman Spectroscopy.

We also offer other traditional chemical, thermal, and mechanical characterization.