Turning pain into purpose: Engineering students create breakthrough burn bandage

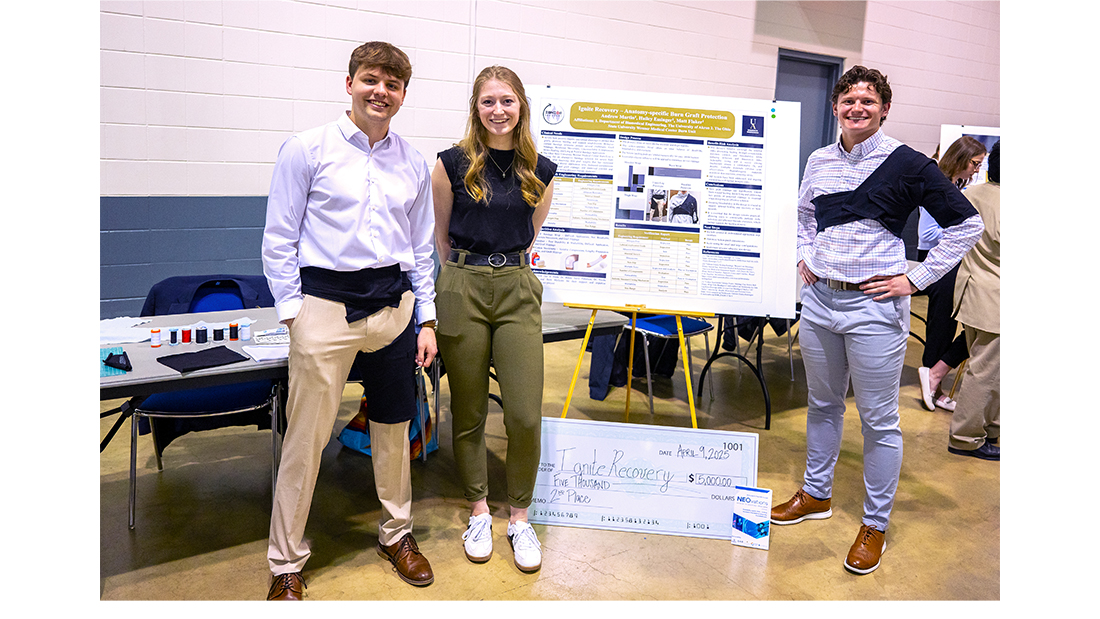

(l to r) Matthew Flaker, Hailey Essinger and Andrew Martin

(l to r) Matthew Flaker, Hailey Essinger and Andrew Martin

What began as a senior capstone project for three biomedical engineering students at The University of Akron has evolved into a powerful innovation with the potential to change lives. And it all started with one student's traumatic experience.

Hailey Essinger ’25, from Arlington, Ohio, survived a catastrophic industrial accident two years ago while working near a three-story manganese furnace. When the furnace unexpectedly collapsed, it triggered an ash cloud explosion that engulfed her in flames. Essinger sustained third-degree burns on over 30% of her body — covering her hands, legs, face, neck and hips. She was life-flighted to Wexford Medical Center, where doctors warned her family that she might not walk again or regain full cognitive function. But through a long and painful recovery — including multiple surgeries and skin grafts — she defied expectations.

As she entered her senior year at UA, Essinger knew exactly what she wanted to do: give back to the medical community that helped save her life. Partnering with Dr. Nicole Bernal at The Ohio State University Burn Center, she and her classmates — Matthew Flaker ‘25 of Wadsworth, Ohio, and Andrew Martin ’25 of Kent, Ohio — set out to develop a more effective, patient-friendly burn dressing system.

The team’s product is a modular, reusable burn bandage that better conforms to the contours of skin grafts and stays in place without slipping — solving one of the most frustrating problems burn patients and health care workers face. Traditional bandaging involves gauze, medication and ACE wraps that often slip off, especially in high-mobility areas like the shoulder and armpit. “The industry standard just isn’t good enough,” Essinger explained. “As a patient, I would have benefitted tremendously from something like this. It’s truly a game changer.”

Martin, who led the structural design and FDA documentation process, emphasized their methodical approach. “We spent the first six weeks gathering information before even considering solutions. Hailey was fluent in the real-world issues, and that grounded our brainstorming. We literally started with a bedsheet to test our ideas.”

The final prototype features Velcro-fastening, skin-safe fabrics — white for hospital use and black for at-home wear — and is easy to apply: just lay it down, place the limb on top, and secure. This design minimizes skin trauma, simplifies dressing changes, and increases comfort and mobility for patients.

Flaker praised the guidance of Burnal, who offered weekly feedback. “She loved the prototype and encouraged us to pursue a patent. What started with a sketch on a whiteboard turned into a product we’re proud to show the medical community.”

The team’s work won second place out of 30 teams and a $5,000 prize at the Northeast Ohio Medical University Bench to Bedside Competition. They have filed for a provisional patent and are now surveying burn units across the region to assess interest and continue development.

“Something like this would have changed my recovery experience,” Essinger reflected. “To take that pain and turn it into something that could help others — there’s no greater honor.”

Each team member recently graduated and is heading into impactful careers. Essinger will serve as a construction project management assistant at Brasfield & Gorrie in Nashville, Tenn. Martin will move to Kalamazoo, Mich., to join Stryker’s instruments division. And Flaker will return to Coltene, where he previously co-oped, to engineer dental products. But the bandage they created together may leave their biggest mark.

Their journey proves that with grit, empathy and engineering, even the deepest scars can inspire innovation.

Media contact: Cristine Boyd, cboyd@uakron.edu; 330-972-6476