MECHANICAL ENGINEERING RESEARCH AREAS

NSF I/UCRC Center for Tire Research (CenTiRe)

Working within the NSF I/UCRC program CenTiRe performs industrially-relevant, pre-competitive research via multi-member, sustained partnerships among industry, academe, and government. As the only tire research center within this NSF program, CenTiRe is uniquely positioned to provide its members a cost-effective means to access technical advancement and trained students in the areas of tire and tire related materials, modeling, testing, and manufacturing. More...

3D Printing of Smart Structures

The Advanced Additive Manufacturing Lab (AAML) was established in spring 2011 with various 3D printing capabilities. Multi-material, multi-scale 3D printing of various smart materials is being investigated for artificial skins, structural electronics, biomedical devices, robotic actuators, etc. Multidisciplinary research on manufacturing, materials and applications is under way. More...

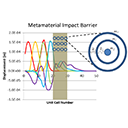

Acoustic/Elastic Composite Metamaterials

Acoustic/elastic composite metamaterials exhibit unique properties not commonly found in natural materials. By specially designing their microstructures, these metamaterials possess negative effective mass density over certain frequency ranges. This implies that stress waves cannot be transmitted through the material, thus enabling control and attenuation of stress wave propagation. This results in interesting applications including vibration control, impact protection, blast wave mitigation and energy harvesting. More...

Computational Aerodynamics

The group’s research efforts are in the emerging areas of computational fluid dynamics (CFD) including vorticity confinement approach for accurate prediction of vortices and aerodynamic drag in air vehicles supported by AFRL, ARO, Navy SBIR and NSF. Other funded projects include coupled molecular and continuum modeling of micro- and nano- fluids in chemical vapor deposition processes, ablation of thermal protecting shield in hypersonic flight and modeling of explosions in offshore oil drilling. More...

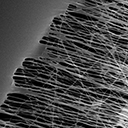

Electrospun Polymer Adhesives

The fibrous adhesives perform like commercial adhesives, with additional benefits of self-cleaning, re-usable and easy re-attachable. Dry adhesives can be obtained from an electrospun non-woven of a spinnable polymer, wherein the polymer fiber forming the non-woven is aligned. The polymeric nanofibers may be formed from a mixture of highly spinnable material, combined with an adhesive component to further enhance the adhesion onto substrates. The non-woven can further be processed by plastic deformation to create microprotrusions. More...

Micro/Nano Engineering Lab

We apply theoretical and numerical methods to solve engineering problems at micro and nano scale. Atomistic modeling (Density Functional Theory, Molecular Dynamics Simulation and Lattice Dynamics), statisticial modeling (Boltzmann Transport Equation and Monte Carlo Method) and continuum modeling (Finite Differential/Volume/Element Methods) are employed to investigate mechanical, thermal and electrical properties of materials. More...

Microelectromechanical Systems Lab

Lab-on-a-chip biosensors. Biomedical devices. Smart sensors for machine health monitoring. Smart structures and devices for aerospace engineering. Micro/nano object manipulation. Micro/nano energy harvesting. Nano devices. Optical MEMS. More...

Multi-scale Modeling of Damage and Failure of Materials

Computational solid mechanics. Constitutive modeling of advanced materials. Nonlinear fracture mechanics. Constraint effect and toughness scaling. Multi-scale modeling of damage and failure of composite materials. Mechanism-based approaches to simulate material failure process and to predict fracture of structural components. Fatigue life prediction. More...

Performance, Failure Mechanisms and Life of High Temperature Composites

Microstructural-based understanding of mechanical performance of ceramic fiber-reinforced ceramic matrix composites. Damage detection and health-monitoring techniques such as acoustic emission and electrical resistivity for composites, structures (e.g., joining and integration of dissimilar materials), and machines. Work with NASA, Air Force, Navy, Goodrich, aero engine companies, and small businesses (SBIR and STTR). More...

Surface Engineering and Advanced Manufacturing

The SEAM group uses various surface processing techniques to engineer beneficial microstructure and/or residual stress changes on metal surfaces to improve the properties and performance. We integrate experiment with multiscale simulation to explore the processing-structure-property relationships. More...

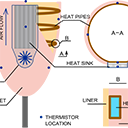

Joint Laboratory for Flow Visualization and Lubrication (LFVL)

The LFVL houses state of the art laser and PIV equipment for non-intrusively visualizing flow and temperature patters in forced as well as natural convection flows. Using long distance microscopy flows can be studied in enclosures as small as 25 microns (MEMS cooing, bearings and seals). The laboratory also houses two high speed (60 krpm) spindle testbeds (40 and 200 HP respectively) for evaluation of performance high speed bearings and contacting and non-contacting seals (brush seals and finger seals). The of the laboratory researchers (faculty and students) have innovated in the area of metal lubricated bearings with self circulation, non-contacting finger seals, in-line debris health monitoring, and intelligent controllable bearings and seals.

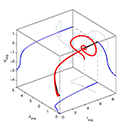

Nonlinear Dynamics and Structural Mechanics

This research area focuses on the investigation of the dynamical response of nonlinear engineering systems, with application to the areas of vibrations and dynamical systems, contact dynamics and control theory, and an underlying theme is the understanding of these systems through the development and analysis of simplified models. More...

Autonomous Systems Laboratory

The laboratory is home to research in robotics, intelligent systems, controls, structural health monitoring, biomedical devices and low-cost remote monitoring platforms. Past work includes brake modeling for Formula One race teams, intelligent monitoring of rocket tests for NASA and design of biomedical devices in the areas of neurosurgery and urology. Current work focuses on developing low-cost monitoring devices based on the Arduino/Raspberry platforms that can be used in multiple verticals such as genomics, food production, water purification and reduction of healthcare costs. More...

Advanced Energy & Sensor Lab

We study energy conversion and storage systems, particularly electrochemical systems such as batteries and fuel cells from multi-physics & multi-scale modeling to design & manufacturing, performance testing, degradation & safety analysis and optimization for portable, vehicle, residential and grid applications. The secondary field is studying measurement systems and sensors. More...

Solid Mechanics

Composite structures; sandwich structures; elastomers; blast and impact mechanics; fluid-structure interaction; damage modeling; FEA. Current interests in the use of foam-core composite sandwich panels for underwater blast mitigation; polymer foam constitutive modeling; multi-scale, damage modeling for FEA simulation of filled rubbers. More...

Human Factors Engineering Lab

The Human Factors Engineering Lab studies the complex interactions between human operator and other system elements in order to enhance system safety and efficiency. Our lab perform research in cognitive system engineering and human decision making in the aviation systems, severe weather forecasting systems, healthcare systems. The lab receives funding from NOAA, FAA, and private industry. The lab director Dr. Chen Ling is also the director of FAA Center of Excellence for Technical Training and Human Performance at University of Akron.