*** Please note, each row and course# listed below is a separate, complete course. ***

Aircraft Tire Design Process

| Course# | Date | Time | Location |

|---|---|---|---|

| 114-1548 | 03/13/2026 - 03/13/2026 | 8:00 AM - 4:00 PM | Microsoft Teams |

| 114-1549 | 06/19/2026 - 06/19/2026 | 8:00 AM - 4:00 PM | Microsoft Teams |

| 114-1550 | 10/08/2026 - 10/08/2026 | 8:00 AM - 4:00 PM | Microsoft Teams |

Online Registration

CEU's: 0.8

Instructor: Christopher Paige

Course Overview

This one-day course will cover and provides an in-depth exploration of the involved engineering, materials science, and regulatory requirements involved in designing aircraft tires. Participants will learn the fundamentals of tire construction, performance criteria, safety standards, and testing methodologies specific to aviation. The program emphasizes the integration of aeronautical engineering principles with advanced manufacturing techniques to ensure reliability, efficiency, and compliance with international aviation standards. The course balances theory, regulation, and practice, making it suitable for aerospace engineering students, aviation maintenance professionals, or industry engineers.

By the end of the course, participants will:

- Understand the unique operational demands placed on aircraft tires.

- Gain knowledge of design parameters, including load capacity, speed rating, and thermal resistance.

- Explore material selection, structural design, and tread pattern optimization.

- Learn about certification processes, testing protocols, and maintenance considerations.

- Apply design principles to case studies and practical scenarios.

Online Course Requirements

We want you to have a great experience participating in our remote (online) courses, and for that, you’ll need the right equipment and internet connection.

Minimum needs are:

- A broadband internet connection that has at least a 2 Mbps upload and download speed.

- A computer (PC or Mac) that can support the latest web browser versions.

- At least 4 GB of RAM and adequate hard drive space.

- A microphone and a speaker.

- International Students: For virtual (online) courses, an additional fee will be assessed to cover the cost of shipping the professional binder (presentation slides), to your address. The cost of international shipping can be significant.

For more information, visit our Online Course Requirements webpage.

Instructor Biography:

Christopher (Chris) Paige holds a M. S. Degree in Plastics Engineering - 2005 (University of Massachusetts – Lowell) and a M.S. Degree in Polymer Chemistry – 1991 (University of Cincinnati). He is a member of Society of Plastics Engineers (SPE), American Chemical Society (ACS) and America Society of Materials (ASM) and has over 30 years’ experience, working in Industry. As a Laboratory Manager, at the University of Akron, Chris performed numerous hands-on plastics processing projects, for domestic and International corporate clients. He is a subject matter expert and has trained clients on Rubber processing (C.W. Brabender’s, 2-Roll Mills, Heat presses), Plastics Processing (Single and Twin-Screw Extruders, Extrusion Blown Molding, Injection Molding, Injection Blow Molding, Thermoforming, Vacuum Forming, blown film and cast film lines), Rubber formulations and Rubber Characterization (MDR, Moonie Viscometers, RPA) and Polymer Characterizations (Thermal Analysis, Mechanical Instron testing, microscopy and spectroscopy).

Section 1: Introduction to Aircraft Tires

- Role of tires in aircraft safety and performance

- Comparison with automotive and industrial tires

- Key operational challenges (speed, load, temperature, environment)

Section 2: Tire Construction and Materials

- Anatomy of an aircraft tire (beads, carcass, tread, sidewalls)

- Material science: natural vs. synthetic rubber, composites, and reinforcements

- Advances in tire materials for durability and sustainability

Section 3: Design Parameters and Performance Requirements

- Load ratings and deflection characteristics

- Speed ratings and high-speed performance

- Thermal management and braking energy absorption

- Tread design for traction, hydroplaning resistance, and wear

Section 4: Regulatory Standards and Certification

- FAA, EASA, and ICAO requirements

- Industry standards (SAE, ASTM, RTCA)

- Certification process and documentation

Section 5: Testing and Validation

- Laboratory testing (static load, fatigue, burst tests)

- Dynamic testing (takeoff/landing cycles, high-speed roll tests)

- Non-destructive inspection methods

- Case studies of tire failures and lessons learned

Section 6: Manufacturing Processes

- Tire building techniques (bias-ply vs. radial construction)

- Vulcanization and curing processes

- Quality control and defect prevention

Section 7: Maintenance and Lifecycle Management

- Inspection and retreading practices

- Common wear patterns and failure modes

- Tire replacement criteria and recycling considerations

Section 8: Emerging Technologies and Future Trends

- Smart tires with embedded sensors

- Sustainable materials and eco-friendly processes

- Innovations in tread design and predictive maintenance

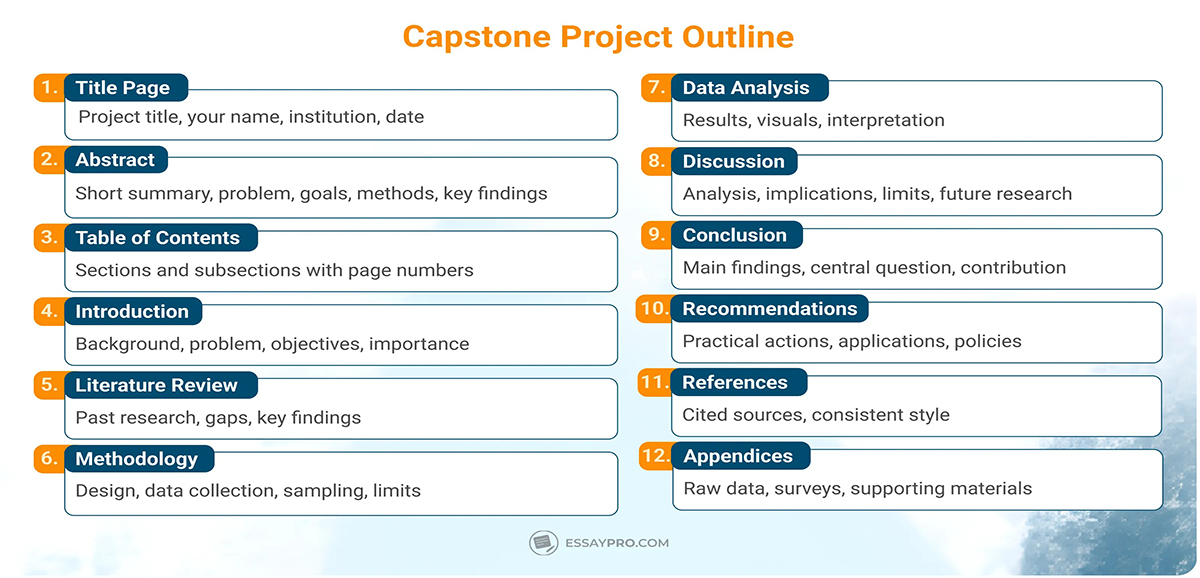

Section 9: Capstone Project Example

- Design a conceptual aircraft tire for a specific aircraft type: Aircraft tires are designed to withstand heavy loads during landing, takeoff, and taxiing. They must support the aircraft’s weight while providing necessary traction for braking and stopping.

- Technical Aspects: Key factors include load rating and analysis, material selection (such as carcass plies to ensure durability and performance under extreme conditions), tread design, ply rating, and a compliance plan.

- Research and Development: NASA conducts research on tire performance, including tread wear, hydroplaning, and gear response to tire failures, which can inform design improvements.

- Industry Insight: Engaging with industry professionals can provide valuable feedback and insight into the latest advancements in tire design.

- Present findings in a technical report and oral presentation, emphasizing real-world applications.