Researcher to reveal energy-saving ‘Living Wall System’ at Bath Nature Preserve

What if the facades of buildings could “sweat,” cooling themselves down on a hot day – and ultimately cutting air conditioning costs?

Dr. Petra Gruber, associate professor in the Mary Schiller Myers School of Art and Department of Biology here, plans to answer that and other questions with her “Living Wall System” (LIWAS): an energy-efficient, multi-paneled wall – composed partly of fungal roots and leaf-shaped, evaporative or “sweating” ceramic panels – that stands at the intersection of nature, art and architecture.

The prototype of the living, breathing and perspiring wall system is being installed at our Biology and Field Station at the Bath Nature Preserve, where Gruber and her team will deliver a public presentation on Tuesday, Oct. 30, at 5 p.m.

VIDEO: “Living Wall”

“We try to integrate characteristics of living organisms into the wall design, so that we can harness some of the intriguing qualities of life into our built surroundings,” said Gruber, an architect and member of our Biomimicry Research and Innovation Center, an interdisciplinary center dedicated to innovation inspired by nature.

Gruber and Ariana Rupp, a doctoral student in our Integrated Bioscience (IB) Program, have been investigating the relationship between leaf morphology, or the shape and texture of leaves, and evapotranspiration, the process by which plants dissipate humidity, and thereby cool themselves, through evaporation – a process analogous to human perspiration.

Improved evaporation and cooling

“We have discovered this relationship between the shapes and the cooling effect that some plants use in their leaves.” Gruber said. “Translating those shapes into technology could be an avenue to improve the efficiency of evaporative systems in facades.”

With the support of a $10,000 Faculty Research Committee Summer Fellowship, Gruber and her team of student researchers – including Rupp, IB doctoral student Thibaut Houette and junior biomedical science major Brian Foresi – have spent the last several months in Gruber’s Biodesign lab translating those shapes into ceramic panels. Drew Ippoliti, assistant professor of ceramics, and Tanya Long, assistant lecturer of art, assisted with design and production.

Gruber explained that the leaf-shaped, porous panels are designed to collect and retain moisture and promote its efficient evaporation. This would help prevent the rapid runoff of rainwater (and the consequent risk of sewage overflow) and allow facades to in effect “sweat” and cool down, reducing the need for air conditioning.

“Cooling down a building needs a lot more energy than heating it up,” she said. “So cooling facades is a really interesting concept for future architectural design.”

Organic building blocks

Gruber’s team – working with Christopher Maurer, founder and principal architect at redhouse studio in Cleveland – also created a set of wall panels made from mycelium material, solidified by the dense network of roots in fungus. When fungal spores are added to a substrate of organic waste, such as wood chips, paper chips, or sawdust, the mycelium grows through the organic substrate. The material has to be placed into a mold or scaffold to determine the shape it will take when solidified by the mycelium. After a drying or baking process, a solid, coherent and lightweight material is formed.

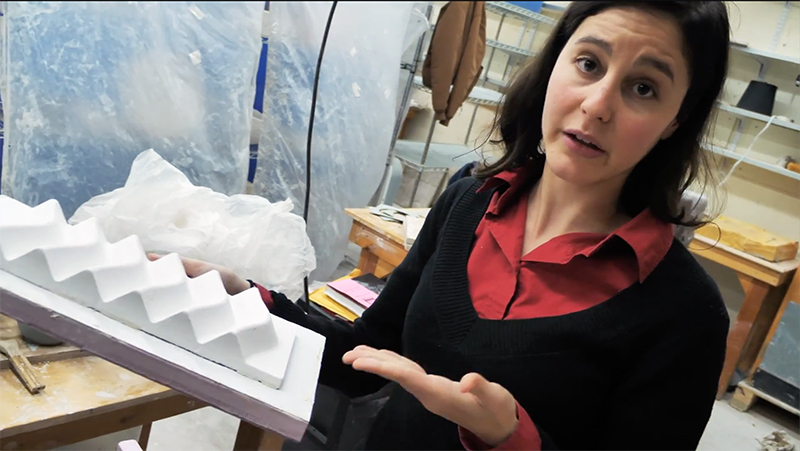

Doctoral student Ariana Rupp, holds a newly fired ceramic panels that will be part of the “Living Wall System.”

“It’s a very sustainable way of making a building material,” Gruber said, pointing out that the mycelium material can be used for insulation and, after it is coated to make it more weather-resistant, for outdoor applications such as cladding and facades – or even for furniture. “And it’s very lightweight … so if you transport the material, if you handle it … that’s all super easy and saves energy and resources for transport as well.”

Like the ceramic panels, the uncoated mycelium material naturally retains moisture, promoting evaporation and cooling.

Gruber is also interested to see what happens when the mycelium panels are exposed to the elements for a long period of time. Specifically, she is eager to see if the panels become inhabited by mosses, ferns and other organisms – indicating their potential to be used as a substrate for “green walls,” also called vertical gardens, which are becoming more common in corporate buildings, airports and other public interiors.

“Considering that more and more people live in urban environments, this reintroduction of green space in urban space is something that people are really after at the moment,” Gruber said.

She added that, over the next few months, the LIWAS prototype will serve as a test bed for different aspects of outdoor performance of the panels, such as thermal behavior, evaporation efficiency and weather resistance, in order to evaluate the potential to test larger-scale prototypes of the experimental panels.