In nature, colors play a vital role in behaviors such as pollination, signaling for mating and defense against predators. Colors are also an important factor in scientific research that can provide the basis for novel printing and anti-counterfeiting applications.

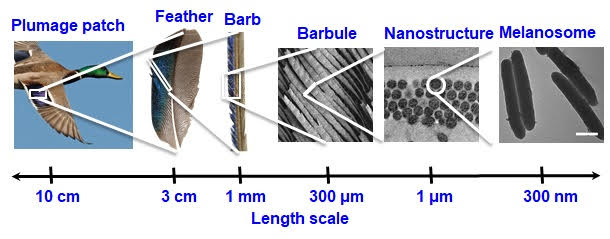

Structural colors are colors that are reflected when microscopic surfaces interfere with visible light. On the peacock, for example, tail feathers have brown pigment, or melanin, but their microscopic structure makes them reflect the dazzling colors we typically see in peacocks — blue, green and turquoise.

It is in this application that researchers from The University of Akron’s (UA) polymer program are exploring. Polymer science doctoral students Mario Echeverri and Anvay Patil, and Dr. Ali Dhinojwala, H.A. Morton Professor of Polymer Science, along with researchers at Northwestern University and Ghent University in Belgium, authored a research article, “Printing a Wide Gamut of Saturated Structural Colors Using Binary Mixtures, With Applications in Anticounterfeiting,” recently published in the American Chemical Society’s journal Applied Materials and Interfaces.

Exploring structural colors

Structural colors are colors that are reflected when microscopic surfaces interfere with visible light. On the peacock, for example, tail feathers have brown pigment, or melanin, but their microscopic structure makes them reflect the dazzling colors we typically see in peacocks — blue, green and turquoise.

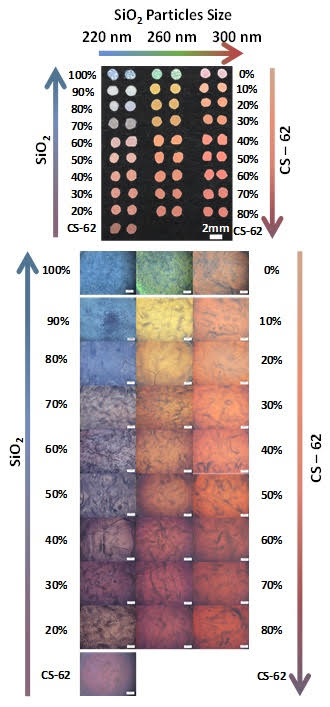

In their study, the researchers proposed structural color printing using simply binary mixtures of particles to produce a broad gamut of saturated structural colors.

Current printing technologies employ pigmentary colors which are composed of toxic metal- or organic-based pigments that are susceptible to degradation and fading over time. The scientists have used a versatile technique to modify substrate surfaces that allows them to print colors on variety of surfaces including metals, plastics, wood, papers and fabrics.

In their study, the researchers proposed structural color printing using simply binary mixtures of particles to produce a broad gamut of saturated structural colors. Essentially, by mixing different-sized particles such as sand (silica) and melanin (a synthetic mimic) in different quantities, the researchers were able to produce vibrant colors, ranging from blue to red, which are similar to what people can observe in bird feathers.

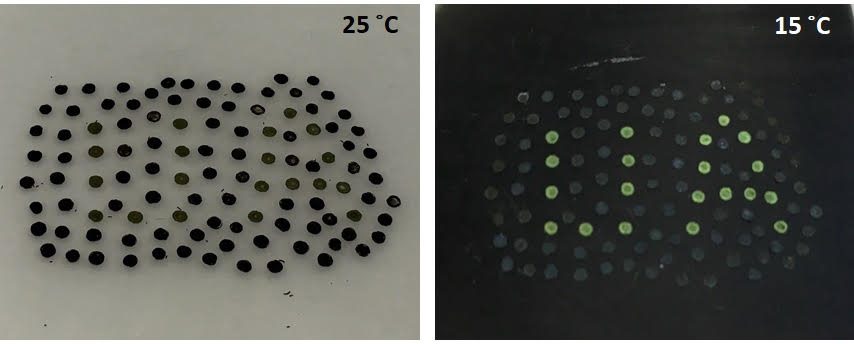

The researchers have demonstrated that the visibility of the colors can be modified by changing the color of the background surface, a property that is highly desirable for anti-counterfeiting applications.

According to the researchers, the methodology revolutionizes the current printing technology by enabling them to print bright, long-lasting and non-fading colors, which was just a conception at one point in time. The simplicity of this approach opens an avenue for easy scale-up operations, such as inkjet printing, and insights into anti-counterfeiting applications, as demonstrated in the study.

According to the researchers, the methodology revolutionizes the current printing technology by enabling them to print bright, long-lasting and non-fading colors, which was just a conception at one point in time. The simplicity of this approach opens an avenue for easy scale-up operations, such as inkjet printing, and insights into anti-counterfeiting applications, as demonstrated in the study.

Research applications

The researchers’ methodology is advantageous over current proposed structural color printing technologies. For instance, the cold-plasma methodology presented in their study has not been used before in context of this application. It has several advantages:

- It eliminates the need for highly concentrated particle suspensions or chemical additives to avoid coffee-ring effect which is detrimental to the print quality.

- This technique can alter the surfaces of a variety of materials such as paper, fabric, metals, inorganics, and polymers, without resorting to wet treatments.

- It facilitates self-assembly of particle mixtures to generate structural colors.

The next phase of this research would be to scale-up operations by testing the system with commercial inkjet printers to enable generation of complex/intricate patterns and designs. Thus, the industries that would be directly interested in this proposed research includes inkjet printing, paint, ink, cosmetics, textiles and plastics.

Co-authors of the study are Ziying Hu and Nathan C. Gianneschi of Northwestern University, and Matthew D. Shawkey of Ghent University.

Media contact: Alex Knisely, 330-972-6477 or aknisely@uakron.edu.