Corrosion engineering program receives $6 million in new funds

The U.S. Air Force Academy and the Office of Corrosion Policy and Oversight have awarded $6 million to The University of Akron’s new Corrosion Engineering and Reliability program, UA CAREs. The funding, a $4.4 million contract and a $1.6 million grant, promises to help launch the program — the nation’s first such baccalaureate program — with a strong start this fall. The Air Force Academy and Office of Corrosion Policy and Oversight are located within the Office of the Secretary of Defense of The United States Department of Defense.

The $1.6 million earmark, which was placed by Sen. Sherrod Brown and supported by Sen. George Voinovich and Reps. Betty Sutton (OH-13) and Tim Ryan (OH-17), will be used to create The National Center for Education and Research on Corrosion and Materials Performance.

“In addition to supporting the delivery of the nation’s first baccalaureate degree in this field, the center places UA in a unique position for delivering research, technology development and materials innovation, thus providing exciting opportunities for our students and faculty, as well as stimulating economic development across a broad range of technology sectors,” says Dr. George K. Haritos, dean of the UA College of Engineering.

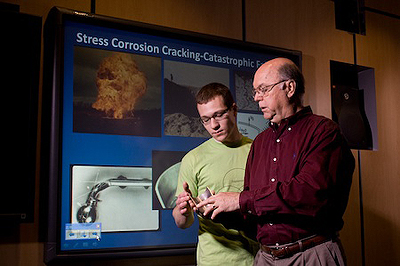

UAkron Corrosion Squad member Matthew Holmer (left) with Dr. Joe Payer, UA research professor of corrosion engineering and reliability.

Specifically, this funding will enable UA to obtain specialized laboratory equipment as well as hire additional faculty to support this new academic program.

UA part of wide partner network

A portion of the $4.4 million contract includes $1 million for applied research to be completed by UA faculty and students on projects that support reducing the military’s cost of corrosion, which has been documented at $22.5 billion annually. As part of its Corrosion Prevention and Mitigation Strategic Plan, the Department of Defense formed the University Corrosion Collaboration (UCC) – a national partnership of faculty and students from six universities working with representatives from government laboratories and military service program offices. Partners include UA, The Ohio State University, University of Southern Mississippi, University of Hawaii, University of Virginia and the U.S. Air Force Academy. Working together, teams will focus on such areas as materials modeling and simulation and corrosion predictability and assessment.

The balance of the $4.4 million will support operations and activities related to the training, workforce development and outreach mission of the center. Under this contract, UA will serve as the lead training developer and integrator for the U.S. Department of Defense Office of Corrosion Policy and Oversight, according to Sue Louscher, UA CAREs project director. The additional funding comes as the program reaches another milestone. After receiving its first funding from the Department of Defense in fiscal year 2008, and additional Congressional support in fiscal year 2009, the program launched its first course this fall. It also opened an undergraduate teaching and research laboratory commissioned for corrosion engineering.

“The nearly 1,000-square-foot lab in Ayer Hall was designed for flexibility to investigate a wide range of important corrosion problems from power plants and pipelines to medical implants and electronic devices,” says Dr. Joe Payer, UA research professor of corrosion engineering and reliability. “Activities will include teaching labs, student projects, multidisciplinary team projects and research.”

Strong interest in program expected

Though formal student recruitment for the first group of corrosion engineering students has been limited to the incoming class of freshmen, initial responses have been positive and scholarships, co-op positions and potential study-abroad opportunities are expected to pique additional strong interest in the program once the semester has begun and for the out years, says Dr. Ed Evans, associate professor of chemical engineering. Evans points out that the program’s rich and growing content emphasizes project management and answers to government’s and industries’ calls for corrosion engineers.

“There is both regulatory push and industry pull for corrosion engineers,” says Evans, noting that the high price of corrosion to industry and government have prompted both entities to advocate mandates for formally educated and trained corrosion engineers.

Long before the UA CAREs’ fall 2010 launch, faculty and students worked to help solve the United States’ $400 billion-a-year corrosion problem. About 20 undergraduate engineering students joined the UAkron Corrosion Squad last spring to participate in a "Fight Against Corrosion.” The multidisciplinary teams addressed corrosion and reliability topics as they worked on military defense-related corrosion problems and shared their projects with representatives of the U.S. Department of Defense.

Senior engineering student Matthew Holmer of Cuyahoga Falls says that he participated in the UAkron Corrosion Squad to expand his knowledge of corrosion engineering. Holmer points out that “corrosion does affect everything. With the corrosion engineering program here,” he says, “opportunities for jobs and education are large.”

For more details, visit UA's Corrosion Engineering and Reliability program.

Media contact: Denise Henry, 330-972-6477 or henryd@uakron.edu.